Building an affordable, sustainable future for all.

Got a question? Feel free to ask

MMC Eco Homes

Sustainable

Homes

Thermal Comfort Design

Dynamic simulation modelling to ensure thermal comfort is maintained.

Net Zero Carbon

On-site renewable technologies installed to offset 100% on carbon emissions generated by the dwellings.

Bespoke Thermal Bridging

Key thermal detials have been modelled and designed to minimize heat loss.

Enhanced Fabric Specification

Significantly improved u-values which will be compliant with future regulation changes.

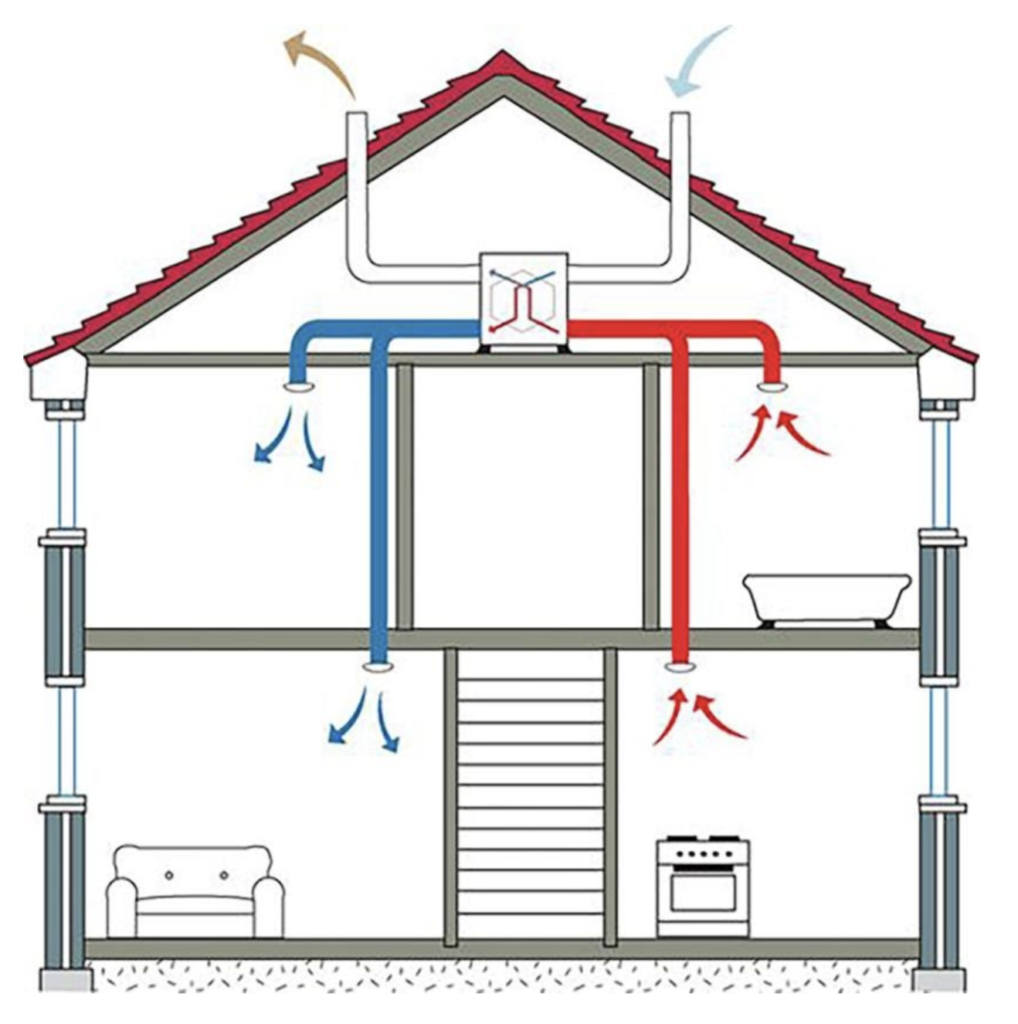

Ventilation

In order to maintain a constant fresh air supply throughout the dwellings and maintain thermal comfort – Heat Recovery Ventilation has been specified for MMC Ecohomes.

Heat Recovery ventilation is the most efficient ventilation option on the residential market and is commonly used in Passive House dwellings.

The system extracts warm stale air from wet rooms such as kitchens and bathrooms, this air is used to temper the incoming fresh air to other habitable rooms.

The tempering of the incoming fresh air significantly reduces the space heating demand of the dwellings and associated carbon emissions.

The proposed ventilation system will have a Specific Fan Power of 0.75 W/l/s and a heat recovery efficiency of 91%.

On a typical new build dwelling the system will more than likely be intermittent extract fans in wet rooms or centralised extract ventilation. Both these systems are known to cause high heating demand and complaints due to drafts in winter

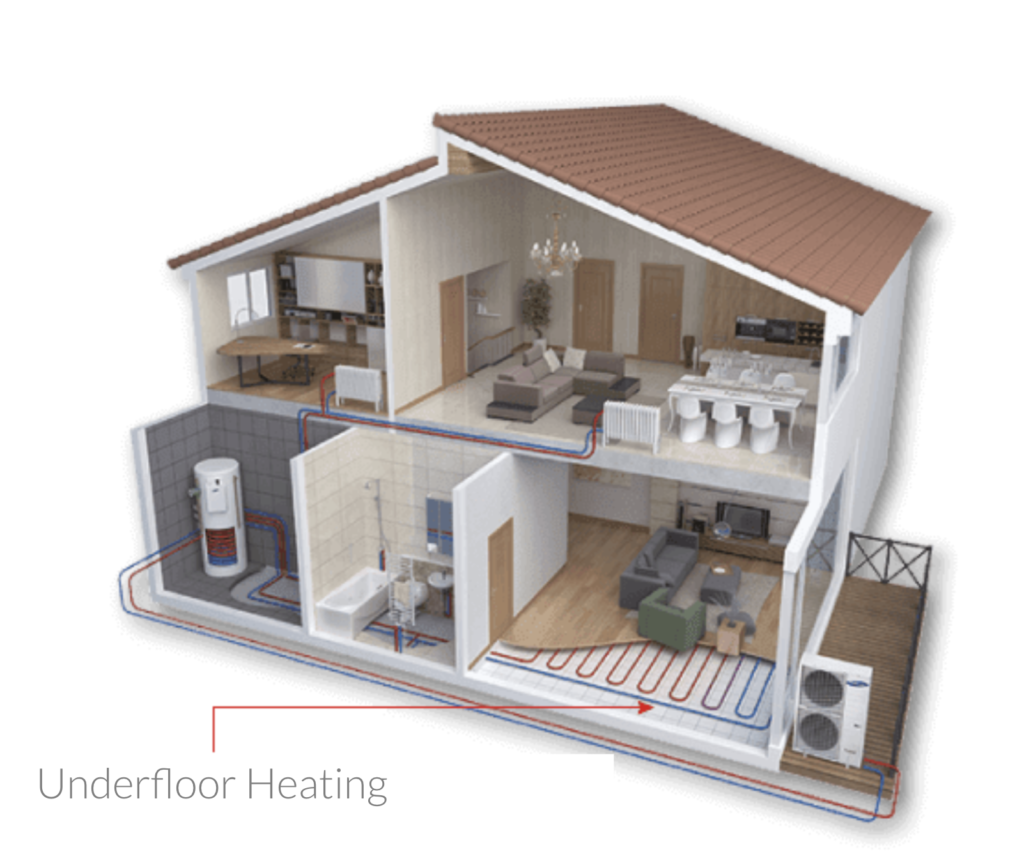

Heating

A detailed feasibility study was carried out to determine the most efficient, practical and beneficial system for the end user. Consideration was given to the offsite construction process.

The proposed space heating and hot water strategy will be an Air to Water Heat Pump, which will emit low temperature hot water via underfloor heating to across both floors of the dwelling.

The use of underfloor heating allows the Heat Pump to operate at its optimal efficiency.

Heat Pumps’ have an efficiency typically in excess of 350% (which offer substantial reductions in carbon emissions. Traditional gas boilers have seasonal efficiencies of typically 91%.

This all electric solution is a future proofed strategy, moving away from fossil fuel energy gas boilers, which will become less prevalent in the market.

Enhanced Fabric Specification

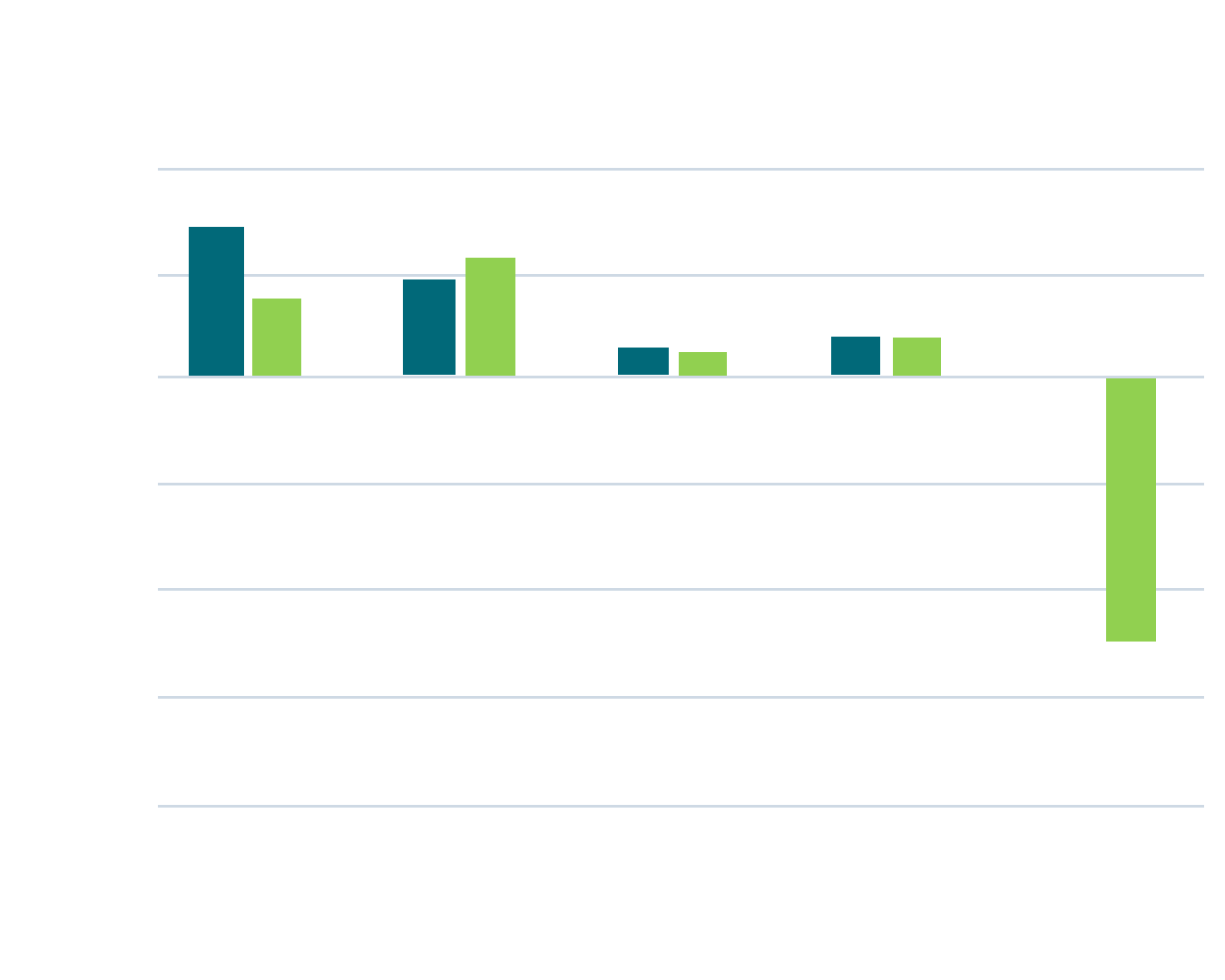

Carbon Emissions Comparison

A typical new build will emit 1715 kgCO2/year.

To meet current building regulation standards, on-site renewables are not necessary

Through enhanced thermal performance, highly efficient space heating and ventilation strategy, MMC Ecohomes achieves Net Zero Carbon

Per annum, MMC Ecohomes will generate more energy that it uses.

An MMC Ecohomes dwelling has net carbon emissions of – (minus) 41.40 kgCO2/year.

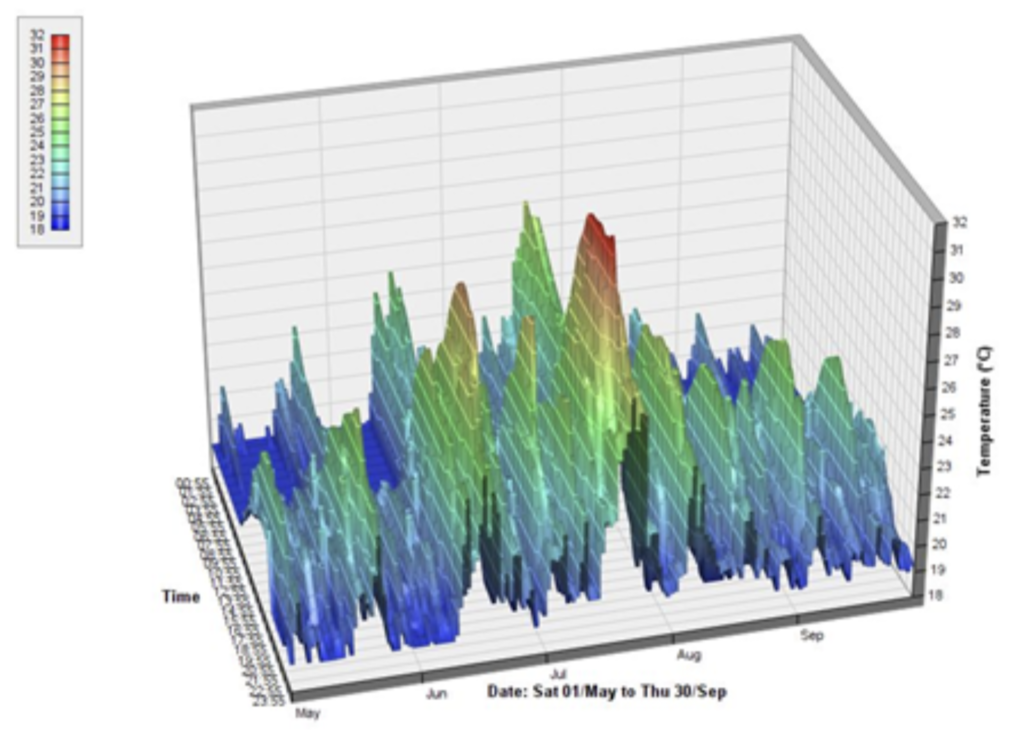

Thermal Comfort

Currently summertime temperatures previous “checked” in SAP Software.

Very basic check and often misses overheating risk. The SAP methodology is the most common method used in the UK and it often misses overheating risks.

To ensure thermal comfort mitigation measures were incorporated into the design, dynamic simulation modelling was carried out using IES software at concept design stage.

This provides a detailed breakdown of the internal temperatures in each habitable room and assesses it against CIBSE TM59 2017 standards for thermal comfort.

The modelling exercise allowed the design team set the glazing specification and ventilation flow rates required to mitigate the overheating risk.

The graphs on the left hand side show the internal temperatures throughout the year. Living Area (Top), Bedroom 01 (Bottom).

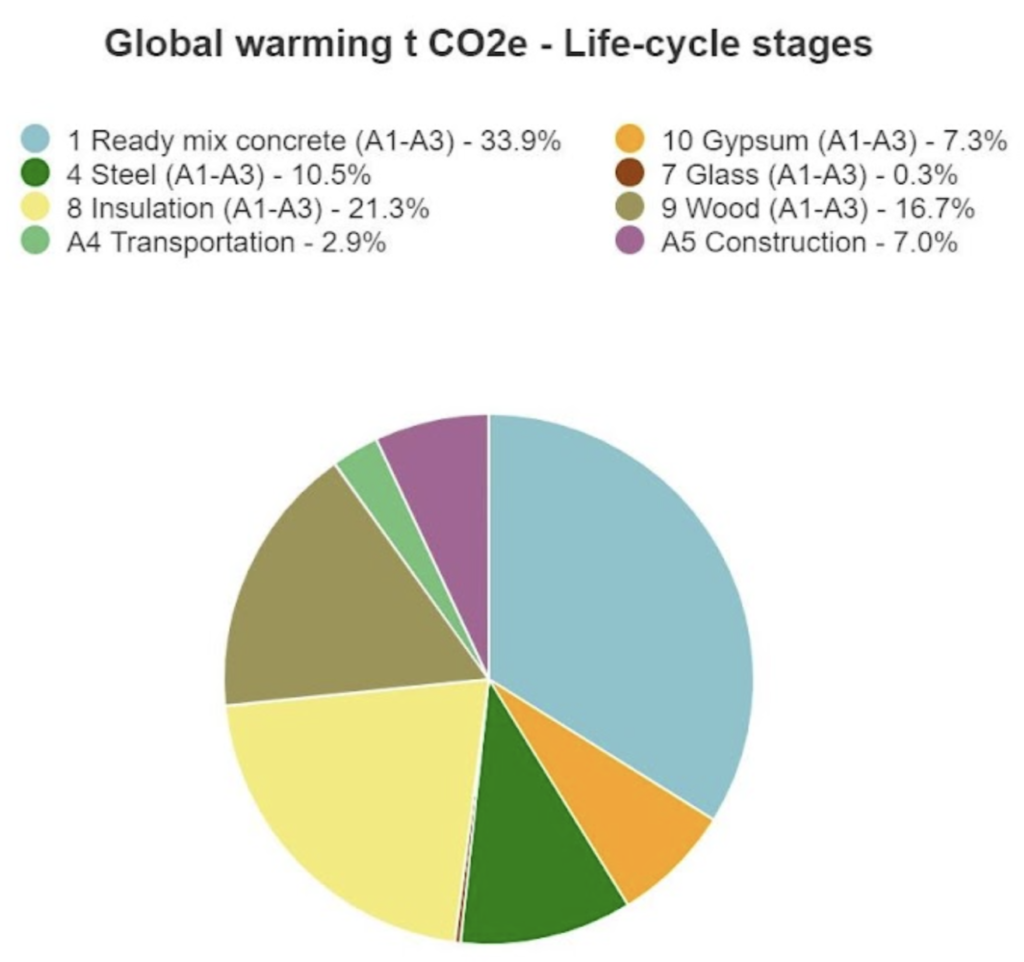

Embodied Carbon

An life cycle carbon analysis was carried out to compare the estimated embodied carbon.

One Click LCA software was used to carry out this calculation.

MMC Estimated tCO2e for A1-A3 material stages is: 105.80 tCO2e

A typical traditional masonry construction of similar size and shape would have embodied carbon of 228.12 tCO2e

This is predominantly down to the significant reduction in concrete required in the MMC design.

Sustainably designed homes

Option to be fully passive

SIPs create a superior building envelope with high thermal resistance and minimal air infiltration – Up to 40% of a home’s heat loss is due to air leakage.

Housing in Britain currently accounts for around 30% of the country’s carbon dioxide emissions. By reducing the amount of energy used in buildings, we can contribute to a clean environment for the future. SIPs can outperform other building methods in virtually every environmental category because the insulation is a core component of the system, rather than an addition.

“Polyurethane SIPs are consistently the more eco-efficient technology. In addition to providing energy efficiency benefits, they have low environmental impact over their life cycle.”

Product comes with option of solar panels, battery and air source heat pump allowing the homes to go “off-grid”

Lower heating costs, helping to reduce fuel poverty

We will continue to reinvest in R&D to find the most efficient renewable sources available